Boron phosphides (BP and B12P2) are characterized by high hardness (Hv > 30GPa), low density, high thermal conductivity and a high thermal and chemical stability (up to 1500K in air).

They can be used in many industries including automotive, mechanical engineering and mining as cutting tools, construction part or wear-resistant coatings.

However, these promising two materials are not yet industrially used because of the lack of mass production method. Currently polycrystalline boron phosphides powders are traditionally synthesized by slow processes requiring toxic and aggressive reagents and high energy.

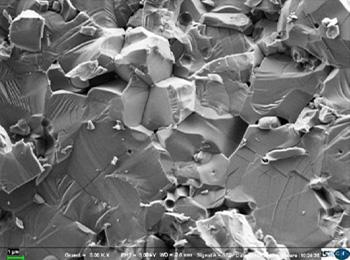

Two new approaches of producing boron phosphide powders have been discovered and patented. These 2 processes, SHS (Self-Propagating High-Temperature Synthesis) and mecanochemistry, enable to synthesize either BP or B12P2 nanopowders with high purity (>97%), from readily available and non-toxic reagents. These new fast, safe, reproducible and scalable syntheses now enable the development of a wide use of boron phosphides.

2 patent families : WO2015097244, WO2016184608

Boron phosphide - BP - B12P2 - Synthesis - SHS - Mecanochemistry - High hardness - Hard material - Ceramic

Erganeo is at your disposal.