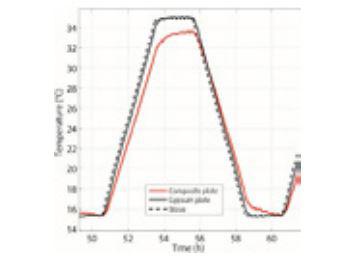

PCM improves thermal performances of materials by delaying temperature increase and decrease and by mitigating the temperature peaks. Most PCM available are based on state change implying solid and liquid transitions which present major issues such as leakage risks and volume variations.

Our technology is based on a solid-solid phase change material that avoids any of these issues. The temperature of phase change can be tuned between 20°C to 65°C according to the application. The PCM presents a Shore hardness which allows its grinding up to grain size lower than 50 μm. The grain size of the PCM can be controlled by sieving for injection in different matrixes (plaster, plastics...). The environmental impact of the PCM is limited, as the synthesis process does not involve any solvent or catalyst.

Patent application WO2017198933A1

Solid-solid Phase Change Material - Thermal energy storage - Phase shift - Energy efficiency - Thermal comfort - Sustainable building

Erganeo is at your disposal.